Yanmar says that its engines will meet anticipated emissions requirements for Europe

Engine technology is advancing, with lower emissions, lower fuel consumption and longer service intervals being key developments - Mike Woof reviews some of the latest developments

A huge investment in diesel engine technologies in recent years has seen manufacturers develop low emission diesels that are quieter, cleaner and use less fuel, while in many instances delivering more power. For machine manufacturers this has been a major benefit, allowing them to meet tougher regulations on noise and exhaust emissions, while also meeting customer needs for better fuel consumption. These newer engines with their better power densities have also allowed equipment manufacturers to select diesels with smaller blocks in many cases.

High pressure, common rail fuel injection and advanced turbocharging systems have been at the heart of the engine developments. Meanwhile an array of sophisticated after-treatment packages have also been developed that are rugged enough to cope with the tough construction working environment.

The engineering challenges have been substantial, with a need to find space for bulky aftertreatment packages and deal with the increased cooling needs, while simultaneously reducing operating noise, much of which is generated by cooling fans. For the developed markets of North America and Europe, this has provided newer cleaner engines that meet the much tougher Tier 4 Final and Stage IV emissions targets respectively. And other territories too are looking to implement stricter emissions controls, most notably with China introducing new requirements during 2015 that will be broadly similar to the earlier Tier 3/Stage IIIA legislation of North America and Europe.

But all this technology has come at a cost. These new engines are more expensive due in part to the additional systems they feature, such as for aftertreatment, as well as for the more complex fuel injection and turbocharging technology they require. And manufacturers have quite understandably had to account for the not inconsiderable development costs in the price of these new generation engines.

This has been only part of the story however, as the low emission engines can only be used in markets where there is a supply of good quality fuel that is low in sulphur. High sulphur fuels can wreck the new generation of low emission engines, attacking the high pressure injection systems and causing rapid corrosion of critical components that is costly to repair. As a result there has been parallel development of diesels for emergent markets where emissions controls are less strict. And these engines have been also able to benefit from some of the technological advances. Meanwhile some engine firms have even developed systems that allow qualified technicians with the right equipment to de-certify low emission engines, so that they can be used in markets where there are less strict regulations and where only lower quality fuels are available. This last point is of importance as it has successfully tackled the issue of secondhand machine sales from developed markets to emergent territories, providing a key benefit for manufacturers, dealers and customers alike.

During 2015 this pace of development will continue; several of the major engine firms will be unveiling sophisticated new technology, with a strong focus on meeting the Tier 4 Final/Stage IV requirements.

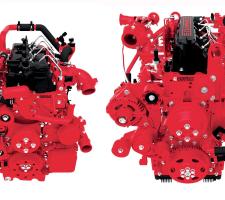

196 Cummins is extending its QSF engine range, with variants aimed at the requirements of the European and US rental equipment markets, as well as advanced new turbocharger systems. The latest QSF engine variants span the 37-55kW power range. A variant of the QSF2.8 is being introduced without charge air cooling (CAC), so as to offer a cost-effective solution for engine installations where space is an issue. The QSF3.8 meanwhile is being offered at a 55kW power rating that is equipped with a diesel oxidation catalyst (DOC), so as to offer the same low maintenance needs as the smaller QSF2.8 engine. The firm is aiming to meet the needs of the rental market by offering engines that are simpler and with lower maintenance needs.

The simplified non-CAC version of the 2.8litre QSF benefits from advances in fuel injection and combustion technology so as to retain torque and power without requiring high-density airflow. Removing the CAC system has helped to lower the cooling requirements, which makes a significant reduction in the space required as well as reducing the need for noise attenuation. The QSF2.8 without CAC is available at 37-48kW power ratings, in addition to the existing QSF2.8 variants with CAC with power ratings from 37-55kW.

Meanwhile the QSF3.8 is now available in a 55kW rating, bringing the benefit of the lower maintenance Cummins DOC-only to a broader range of rental equipment applications.

The firm’s turbocharging technology is also being advanced with the introduction of a new variant for engines of 16litres and above. The Series 900 has been designed to meet the diverse duty cycles of this engine range and for applications with power requirements from 294-4,707kW.

Advanced technologies used in the Series 900 will also be introduced to the existing Series 800 and Series 1000 turbochargers, further developing their performance. And Cummins Turbo Technologies has also unveiled plans for further investment in future technology solutions, specifically to improve fuel efficiency.

German company201 DEUTZ says that it is moving ahead of the legislative process by ensuring that in the 2.9-7.8 litre range, its new diesel engines already meet the forthcoming Stage V mobile machinery emissions standard. This is expected to apply to Europe from January 2019. The company says that the Stage V engines will give its customers long-term planning certainty. According to DEUTZ, its diesel particulate filter (DPF)-equipped engines in the 2.9-7.8litre range already meet the limits envisaged for 2019.

In anticipation of the fourth emissions standard (EU Stage IV/US EPA Tier 4), introduced in 2014, DEUTZ had already redesigned substantial parts of its engine range from scratch and had implemented the latest exhaust aftertreatment technology. In conjunction with a sealed DPF, these engines already conform to Stage V.

Power density is a key issue for7935 FPT Industrial, which claims that its new Cursor 16 engine delivers 18litre performance from a 13litre package. The engine is said to suit installations such as wheeled loaders, excavators and dump trucks. The new engine is designed for heavy-duty applications and meets the latest Tier 4 Final/Stage IV emissions requirements due largely to the development of FPT’s patented HI-eSCR system. This is also the first FPT Industrial engine to feature a compact graphite iron (CGI) cylinder head, with this high performance material offering a combination of high thermal and mechanical resistance. The engine also benefits from a third generation common rail, high-pressure fuel injection system working at pressures of up to 2,200bar. The engine can deliver up to 570kW with maximum torque of 3,320Nm at 1,500rpm in its single stage turbo version and up to 630kW with maximum torque of 3,500Nm at 1,400rpm when available in its double stage turbo version.

2278 Kohler is widening its line-up of Kohler direct injection (KDI) diesel engines with the introduction of its KDI 3404 model. This diesel is manufactured in the 2277 Lombardini plant in Italy, which Kohler bought in 2007 and the engine is offered in two basic variants and four power ratings. The KDI 3404 meets the Tier 4 Final, Stage IV emissions regulations due to its compact, high-efficiency selective catalyst reduction (SCR) system. Another important factor in the firm achieving the low emissions is its high-pressure common rail injection system, which operates at 2,000bars as well as an electronically controlled EGR valve for recirculating exhaust gases. Performances are achieved without the use of a DPF.

The engine is available in two four-cylinder models with a displacement of 3.4litres: KDI 3404TCR (Turbo Common Rail) rated at 56.4kW (compliant to Tier 4 Interim/Stage IIIB standards) and the KDI 3404TCR-SCR (Turbo Common Rail with SCR) rated at 100kW (compliant to Tier 4 Final/Stage IV standards), and also available with power ratings of 75kW and 90kW.

2394 Volvo Penta has redesigned its 5litre and 8litre engines, making them Stage IV/Tier 4 Final-compliant while it is also introducing a new D11 diesel that also meets the Stage IV/Tier 4 Final requirements. Developed in coordination with the 3970 Volvo Group, the D5 and D8 engines are based around a newly-designed platform. These engines are available in Tier 4 Final/Stage IV emissions configuration for sale into the US and Europe, as well as Tier 2/Stage II/ and Tier 3/Stage IIIA variants for emergent markets.

The engines all share the same basic block and with the turbocharger located in the same spot, but with varying fuel injection and aftertreatment technology as required for the specific sales territory. The engines also share common electronics technology that allows them to communicate using the same protocol, regardless of emissions level.

Features include increased displacement, stiffer blocks and higher torque at low speeds, as well as up to 2.5% fuel savings, compared with the engines being replaced. The D5 and D8 feature selective catalytic reduction (SCR) aftertreatment to meet the Tier 4 Final/Stage IV requirements, a technology that is proven, durable and reliable according to the firm.

Meanwhile7139 Yanmar says that its three and four cylinder TNV-CR series industrial diesel engines will be compliant with the coming EU Stage V regulations in 2019. The firm says it has stayed ahead of the introduction of emissions regulations, ensuring that its diesel were compliant with the Tier 4 Interim/Stage IIIB requirements before they were implemented. The engines deliver 19-56kW and are also compliant with the Swiss OAPC ordinance regulations.

A huge investment in diesel engine technologies in recent years has seen manufacturers develop low emission diesels that are quieter, cleaner and use less fuel, while in many instances delivering more power. For machine manufacturers this has been a major benefit, allowing them to meet tougher regulations on noise and exhaust emissions, while also meeting customer needs for better fuel consumption. These newer engines with their better power densities have also allowed equipment manufacturers to select diesels with smaller blocks in many cases.

High pressure, common rail fuel injection and advanced turbocharging systems have been at the heart of the engine developments. Meanwhile an array of sophisticated after-treatment packages have also been developed that are rugged enough to cope with the tough construction working environment.

The engineering challenges have been substantial, with a need to find space for bulky aftertreatment packages and deal with the increased cooling needs, while simultaneously reducing operating noise, much of which is generated by cooling fans. For the developed markets of North America and Europe, this has provided newer cleaner engines that meet the much tougher Tier 4 Final and Stage IV emissions targets respectively. And other territories too are looking to implement stricter emissions controls, most notably with China introducing new requirements during 2015 that will be broadly similar to the earlier Tier 3/Stage IIIA legislation of North America and Europe.

But all this technology has come at a cost. These new engines are more expensive due in part to the additional systems they feature, such as for aftertreatment, as well as for the more complex fuel injection and turbocharging technology they require. And manufacturers have quite understandably had to account for the not inconsiderable development costs in the price of these new generation engines.

This has been only part of the story however, as the low emission engines can only be used in markets where there is a supply of good quality fuel that is low in sulphur. High sulphur fuels can wreck the new generation of low emission engines, attacking the high pressure injection systems and causing rapid corrosion of critical components that is costly to repair. As a result there has been parallel development of diesels for emergent markets where emissions controls are less strict. And these engines have been also able to benefit from some of the technological advances. Meanwhile some engine firms have even developed systems that allow qualified technicians with the right equipment to de-certify low emission engines, so that they can be used in markets where there are less strict regulations and where only lower quality fuels are available. This last point is of importance as it has successfully tackled the issue of secondhand machine sales from developed markets to emergent territories, providing a key benefit for manufacturers, dealers and customers alike.

During 2015 this pace of development will continue; several of the major engine firms will be unveiling sophisticated new technology, with a strong focus on meeting the Tier 4 Final/Stage IV requirements.

The simplified non-CAC version of the 2.8litre QSF benefits from advances in fuel injection and combustion technology so as to retain torque and power without requiring high-density airflow. Removing the CAC system has helped to lower the cooling requirements, which makes a significant reduction in the space required as well as reducing the need for noise attenuation. The QSF2.8 without CAC is available at 37-48kW power ratings, in addition to the existing QSF2.8 variants with CAC with power ratings from 37-55kW.

Meanwhile the QSF3.8 is now available in a 55kW rating, bringing the benefit of the lower maintenance Cummins DOC-only to a broader range of rental equipment applications.

The firm’s turbocharging technology is also being advanced with the introduction of a new variant for engines of 16litres and above. The Series 900 has been designed to meet the diverse duty cycles of this engine range and for applications with power requirements from 294-4,707kW.

Advanced technologies used in the Series 900 will also be introduced to the existing Series 800 and Series 1000 turbochargers, further developing their performance. And Cummins Turbo Technologies has also unveiled plans for further investment in future technology solutions, specifically to improve fuel efficiency.

German company

In anticipation of the fourth emissions standard (EU Stage IV/US EPA Tier 4), introduced in 2014, DEUTZ had already redesigned substantial parts of its engine range from scratch and had implemented the latest exhaust aftertreatment technology. In conjunction with a sealed DPF, these engines already conform to Stage V.

Power density is a key issue for

The engine is available in two four-cylinder models with a displacement of 3.4litres: KDI 3404TCR (Turbo Common Rail) rated at 56.4kW (compliant to Tier 4 Interim/Stage IIIB standards) and the KDI 3404TCR-SCR (Turbo Common Rail with SCR) rated at 100kW (compliant to Tier 4 Final/Stage IV standards), and also available with power ratings of 75kW and 90kW.

The engines all share the same basic block and with the turbocharger located in the same spot, but with varying fuel injection and aftertreatment technology as required for the specific sales territory. The engines also share common electronics technology that allows them to communicate using the same protocol, regardless of emissions level.

Features include increased displacement, stiffer blocks and higher torque at low speeds, as well as up to 2.5% fuel savings, compared with the engines being replaced. The D5 and D8 feature selective catalytic reduction (SCR) aftertreatment to meet the Tier 4 Final/Stage IV requirements, a technology that is proven, durable and reliable according to the firm.

Meanwhile