The guardrail sections from Roadis are available in a novel array of painted finishes

A series of new guardrail technologies and barrier developments are now coming to market - Mike Woof writes

An array of technical developments is helping improve highway safety for road users. New barrier and guardrail technologies can offer greater conspicuity so as to alert drivers, along with better restraint capabilities.

7823 Gregory Industries offers a wide range of steel and cable barrier types and has now developed an attachment system for international use. This fixes the guardrail to the post and in the event of an impact, the system releases and allows the guardrail to rise up so that a vehicle cannot go over the top. This is a proprietary system in the US and the company is now looking to market the product internationally.

Long working life is claimed for the steel guardrail products available from French manufacturer7824 Roadis, a subsidiary of Galva Union. The company has a strong market share in France but has not focussed on exporting its products in the past, a situation that is now changing as the company is looking to increase its sales. The range has previously been available to meet the French barrier standards only but the company is now working on products to meet the European EN1317 requirements, with one of the first being its latest bridge parapet range. This has received approval for use in Europe from the French 2905 LIER testing body. The parapets are designed to the W4 (1.3m) working width and meet the H3 containment level, with a dynamic deflection of 1.2m. Post spacings range from 2.2-2.5m for this three beam design and the system can be adapted to existing bridges according to the firm, with a choice of both mechanical anchorages and chemical fixings.

Another novel feature of the firm’s range is the option for steel guardrail painted to meet specific customer requirements. Powder coating is used and options include a wood finish or grass appearance. As the paint layer is on top of a conventional galvanised coating, long life is claimed in operation. The firm is installing a new red barrier on an expressway that runs parallel to a railway in the South of France. The expressway features several bridges along the route and the Roadis barrier was selected for the application due to its long working life and high redirective performance in the event of an impact.

French firm7825 Tertu has been a pioneer of guardrails designed for use in scenic areas and featuring wooden surfacing with a steel core. The company uses Douglas Fir for the barriers as this is mechanically strong and can be treated with proven products to ensure long working life, as well as being a fast growing tree. A spokesperson for the company said, “For each tree we harvest, we put another down.”

The company has developed a strong share of the European market but now also has a licensee in China, as well as supplying products to the Latin American market. Different barrier products are available from the firm to meet European as well as US requirements and development continues, with new units due to be ready for the market later this year. The spokesperson said, ”Now we have certified products for Europe and two more in development, plus one we have approved in the US.”

7829 Gibraltar Cable Barrier Systems says that its new system offers customers the benefits of high safety standards as well as cost-effectiveness. Ease of installation is said to make the cable barrier system quick to set up and also helps lower costs. Crucially, high vehicle containment and redirective capabilities are claimed and the system has been successfully tested to the NCHRP 350 TL-3 and TL-4 requirements for use in North America, which will also allow it to be used in most Latin American countries as well as many in the Middle East and Africa. Post spacings for the system can be at distances of up to 9.14m and it can be used in applications with slopes of up to 4:1, a feature that boosts its versatility in terms of installation. The system can feature three or four strands of cable and suits use in highway median applications while its ability to redirect errant vehicles means it offers increased safety over earlier generation products.

Another new system for the cable barrier segment comes from7830 Trinity Highway International. The company has improved its CASS cable barrier technology to upgrade its vehicle redirective performance. The CASS system suits applications in highway median installations to prevent crossover crashes. A key feature is the post design with its novel wave-shaped slot, which the firm says combines with the cable position to maximise vehicle restraint performance. A key feature of the CASS system is that it meets the US NCHRP 350 TL-3 as well as European EN1317 requirements, suiting it to applications in North America and Europe, as well as the wide array of countries in South America, the Middle East, Asia and Africa accepting one or the other set of standards. Upgrades to the CASS system means it is compliant to the European EN1317-2, Class N2, H1, H2, L1 and L2 standards, while being CE marked to EN1317-5.

An important feature is that the widened cable spread offers optimum restraint capabilities for a wider range of vehicles. The three-cable, high tension system can be supplied pre-stretched or with standard cable options, while other options include NCHRP 350 Report 350 compliant Cable Terminal or non-350 Cable Anchor variants. The cables are aligned within the body of the posts, which can be driven, placed in steel sleeves or placed in steel sleeves set in concrete footings. Spacings can be from 2-5m for the C-shaped cable posts, which measure 100mm x 50mm x 4mm. The system requires minimal maintenance as well as allowing for quick repairs after each impact. In addition, the 19mm diameter, pre-stretched and tensioned cables offer low maintenance needs.

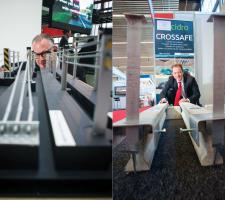

7826 Cidro has developed a straightforward system for protecting motorists from severe impacts with culvert ends. The company’s CROSSAFE device is made from concrete and galvanised steel components and is installed at the end of a concrete culvert. Should a vehicle run off the road into the ditch, the CROSSAFE device prevents sudden impact with the concrete culvert end. Instead, the vehicle impacts against the sloping components of the CROSSAFE system and is diverted upwards, vastly reducing the deceleration rate and reducing the G-forces experienced by the occupants. The CROSSAFE system provides protection for occupants in passenger cars or motorcycle riders and its performance has been verified in an accredited crash test laboratory to approved European vehicle restraint standards.

Giorgio Munaretto is product manager for the system and said that the patent is now in place in Europe and pending for the US. The company is now looking for international distribution in markets outside of Spain and is particularly keen to sell the system in developed markets such as Europe and North America.

The DUO-Gate system from7827 Heintzmann is a high performance barrier that doubles as a gateway that allows emergency access. The system is suited to installations in and around tunnels and at toll areas for bridges. It offers crossing widths of 5m or 9m and can be raised to allow emergency vehicles to pass from one carriageway to another in the event of a crash or fire. The product uses a proven profile and is 815mm high by 610mm wide at the base, while the sections are 20.3m long and 22.3m long for the versions offering 5m and 9m width crossing widths respectively. The units are already proven and have been installed in tunnels in the Netherlands for example. The units have passed the TB11 and TB51 tests and feature H2 containment ratings under the EN1317-2 standards. The units open hydraulically in two minutes and are said to be able to operate in all climactic conditions, with a choice of manual or automatic operation available.

Australian firm7828 Saferoads is offering an improved roadside protection product in the shape of its new Omni Stop Bollard. The products are suited to installations such as around construction work zones or pedestrian and commercial areas, where there may be site personnel or people congregating alongside a busy roadway. The Omni Stop Bollards can be spaced so as to allow free access for pedestrians or cyclists, while providing protection from errant vehicles. The Omni Stop Bollard is made from steel and has been tested to Australian standards with a 1.6tonne vehicle impacting at a speed of 60km/h, deflecting by no more than 300mm at its top. A novel energy absorbing cartridge encased in a concrete footing helps the product cope with impact forces. In the event of an impact, the cartridge will deform and absorb the kinetic energy, safely decelerating the vehicle and preventing serious injury.

Italian company333 Snoline says that its TAU TUBE redirective crash cushion offers low cost crash protection. Paula Ferraris, communications & marketing manager for the firm said, “It is like the previous Tau but with a new impact absorbing system. It can stop a car travelling at 110km/h in less than 7m.”

The system is said to be simple to install and is designed for long life, with a galvanised steel structure and meets the European EN1317-3 safety criteria. The impact absorbing beams are made from aluminium and are resistant to corrosion, adding to the long wear life performance. This high performance crash cushion is said to suit installations in narrow spaces such as tunnels. The parts can be interchanged with components from other TAU units, reducing inventory and maintenance costs for the user. The product has been designed for versatility and can be attached to virtually any safety barrier, including double or triple beam guardrail and concrete types.

Meanwhile improved safety levels are claimed for the new end terminal developed by Snoline’s sister firm,2438 Lindsay. The X-LITE Terminal is said to offer excellent impact performance at an affordable price, as well as ease of installation. The product has been tested to NCHRP 350 TL-3 requirements and the firm is said to have been engineered for maximum interchangability for either flared or tangential installations.

The unit is offered with heights of 710mm or 790mm, measures 11.43m long and features a W-beam design, which telescopes during impact. It is made from many standard, non-proprietary W-beam guardrail components, which helps reduce the cost and has a non-extruding, fixed head design that is said to offer both safe and consistent performance. The firm offers the product with a choice of I-Beam steel posts with either wood or composite blockouts, depending on needs of the client and the application. The firm has designed the system for versatility and it can be attached to a concrete barrier by using standard transition components. It is suited for use at the side of a road where a recommended clear zone and recoverable slope can be attained.

4017 Delta Bloc is offering two new pre-cast barrier products, aimed at different applications. The SB50 is a lightweight pre-cast system with a slimline design, intended for use in workzone applications. Each standard unit is 6m long and weighs 750kg, with a base width of 24cm. The product features a 70cm working width and provides a T3 containment level. The novel joint system means that a crew of two can install 400m/hour and the design is said to have improved drainage performance due to its innovative base design. A spokesperson for the firm said, “It’s the lightest approved system on the German market. It has a slip and lock system and sits on elastomeric pads.”

The City Bloc security barriers meanwhile are designed for use in urban workzone areas, alongside roads with speed limits of 50km/h. Holes in the top of the units allow signs to be fitted and the versatile system comes with an array of standard straight, curved and corner sections. Steel couplings mean the units are quick to join together and the elements can be lifted into place using a fork lift truck, skid steer loader or backhoe loader. Channels in the base of the sections allow for cabling and also maximise drainage. The New Jersey profile means that these modular units are stable when installed while the design allows multiple sections to be stacked for storage when not in use. The company spokesperson said, “You have plug-in options and you can slot in signs or advertising hoardings.”

An array of technical developments is helping improve highway safety for road users. New barrier and guardrail technologies can offer greater conspicuity so as to alert drivers, along with better restraint capabilities.

Guardrail

Long working life is claimed for the steel guardrail products available from French manufacturer

Another novel feature of the firm’s range is the option for steel guardrail painted to meet specific customer requirements. Powder coating is used and options include a wood finish or grass appearance. As the paint layer is on top of a conventional galvanised coating, long life is claimed in operation. The firm is installing a new red barrier on an expressway that runs parallel to a railway in the South of France. The expressway features several bridges along the route and the Roadis barrier was selected for the application due to its long working life and high redirective performance in the event of an impact.

French firm

The company has developed a strong share of the European market but now also has a licensee in China, as well as supplying products to the Latin American market. Different barrier products are available from the firm to meet European as well as US requirements and development continues, with new units due to be ready for the market later this year. The spokesperson said, ”Now we have certified products for Europe and two more in development, plus one we have approved in the US.”

Cable options

Cable barriers are widely used in road and highway installations as they are comparatively quick to install, offer good redirective capabilities for cars and trucks and can also be quickly repaired in the event of an impact. US firmAnother new system for the cable barrier segment comes from

An important feature is that the widened cable spread offers optimum restraint capabilities for a wider range of vehicles. The three-cable, high tension system can be supplied pre-stretched or with standard cable options, while other options include NCHRP 350 Report 350 compliant Cable Terminal or non-350 Cable Anchor variants. The cables are aligned within the body of the posts, which can be driven, placed in steel sleeves or placed in steel sleeves set in concrete footings. Spacings can be from 2-5m for the C-shaped cable posts, which measure 100mm x 50mm x 4mm. The system requires minimal maintenance as well as allowing for quick repairs after each impact. In addition, the 19mm diameter, pre-stretched and tensioned cables offer low maintenance needs.

Specific applications

Spanish firmGiorgio Munaretto is product manager for the system and said that the patent is now in place in Europe and pending for the US. The company is now looking for international distribution in markets outside of Spain and is particularly keen to sell the system in developed markets such as Europe and North America.

The DUO-Gate system from

Australian firm

Italian company

The system is said to be simple to install and is designed for long life, with a galvanised steel structure and meets the European EN1317-3 safety criteria. The impact absorbing beams are made from aluminium and are resistant to corrosion, adding to the long wear life performance. This high performance crash cushion is said to suit installations in narrow spaces such as tunnels. The parts can be interchanged with components from other TAU units, reducing inventory and maintenance costs for the user. The product has been designed for versatility and can be attached to virtually any safety barrier, including double or triple beam guardrail and concrete types.

Meanwhile improved safety levels are claimed for the new end terminal developed by Snoline’s sister firm,

The unit is offered with heights of 710mm or 790mm, measures 11.43m long and features a W-beam design, which telescopes during impact. It is made from many standard, non-proprietary W-beam guardrail components, which helps reduce the cost and has a non-extruding, fixed head design that is said to offer both safe and consistent performance. The firm offers the product with a choice of I-Beam steel posts with either wood or composite blockouts, depending on needs of the client and the application. The firm has designed the system for versatility and it can be attached to a concrete barrier by using standard transition components. It is suited for use at the side of a road where a recommended clear zone and recoverable slope can be attained.

Workzones

The City Bloc security barriers meanwhile are designed for use in urban workzone areas, alongside roads with speed limits of 50km/h. Holes in the top of the units allow signs to be fitted and the versatile system comes with an array of standard straight, curved and corner sections. Steel couplings mean the units are quick to join together and the elements can be lifted into place using a fork lift truck, skid steer loader or backhoe loader. Channels in the base of the sections allow for cabling and also maximise drainage. The New Jersey profile means that these modular units are stable when installed while the design allows multiple sections to be stacked for storage when not in use. The company spokesperson said, “You have plug-in options and you can slot in signs or advertising hoardings.”