Deck waterproofing remains critical to a bridge’s structural integrity for its design life, explains Cliff Weston, director of Stirling Lloyd

To properly maintain deck waterproofing there must be a willingness to look at solutions based on whole-life costing rather than just short-term initial costs. There are lessons to be learned from examples of prematurely failed infrastructure due to a focus on initial short-term costs.

Not only this, any maintenance required once a bridge has been built could mean putting it out of service, causing disruption to the economy and the local community, as well as having environmental impacts. The overall challenge is to carry out the maintenance work while keeping the bridge in service at all times, completing the works in the shortest possible time avoiding unnecessary costs and disruption.

Effective long-term protection should be a given benefit of any quality waterproofing system, after which speed and ease of the application are, more often than not, the key requirements for waterproofing application. Eliminator,

On one recent contract a requirement was to open the waterway – where the bridges span – at least every hour, which reduced the available productive working hours and consequently outputs per day. However, due to the system’s speed and ease of application, the contractor was still able to coat 2000m2 per day. This helped ensure fast progress on the project, disruption was minimised and the bridges being returned to service on schedule.

Always looking to innovate, Stirling Lloyd’s in-house research and development team developed Bond Coat 3, a durable bond coat to be part of the Eliminator system, which is highly resistant to damage and pick-up by vehicles including site traffic in hot weather and is easily cleaned where contamination occurs. This addition to the Eliminator systems enables the asphalt binder course to be applied immediately or, if programming dictates, allows the system to be trafficked until surfacing takes place.

Production of an initial long-term asset management plan can help keep bridge maintenance to a minimum. However, it will still involve some refurbishment work to ensure bridge longevity and to keep traffic moving as much as possible.

Replacing asphalt pavement and waterproofing on a bridge involves a number of processes, some of which can be affected by unpredictable events. Once a deck is exposed to the elements, inclement weather can quickly deteriorate a surface, leading to unforeseen repairs which might be costly in terms of money and project scheduling. This could severely disrupt asphalt production and placement.

Undertaking the works in small sections is one solution. But this can be very expensive and will usually prolong traffic delays and increase disruption to users for an extended period.

An example of a contract in the US that carried out refurbishment work quickly and efficiently was Fast 14. The project involved 10 weeks of work to replace 14 bridges on the busy I-93 highway near Boston. It was aptly named, as the work would have taken over four years using traditional methods of working and materials.

Following inspection in 2010, the concrete decking and steel beams were found to be failing on the 14 ageing bridges. The Massachusetts Department of Transportation looked to the Federal Highways Accelerated Bridge Construction Programme for ideas on how to keep disruption to a minimum. The following work sequence was decided after a review of the available refurbishment methodologies and materials that could fulfil it and comparing it to the possible environmental and economic costs of years of traffic congestion associated with the alternative.

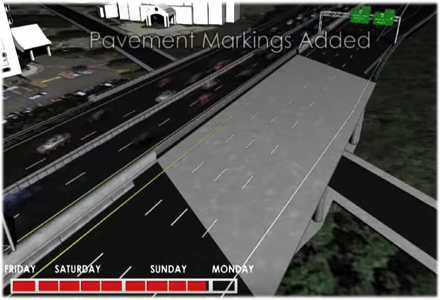

After Friday evening rush hour, traffic flow was changed on the I-93. One of the 14 bridges was then dismantled, new prefabricated concrete bridge panels were put in place and joined together, with rapid setting concrete diaphragms followed by the application of temporary road markings. The new temporary bridge was open by the time Monday morning commuters were on the road.

On a subsequent weekend the Eliminator waterproofing was installed. This involved the spray application of two coats of membrane in two light-coloured contrasting coats to help ensure correct and complete coverage during the required night time application. To give a high friction anti-skid surface, aggregate was broadcast into the second coat of membrane, providing a temporary trafficable wearing surface. Again the bridge was returned to service for Monday morning rush-hour.

When possession could be taken again, the surface of the membrane, which was undamaged by the regular heavy traffic flow, was simply brushed to remove any debris and dirt. Stirling Lloyd’s proprietary bond coat was then applied to provide a bond for the asphalt pavement that followed.

Consequently each ‘new’ bridge was placed and protected over three weekends with no disruption to weekday traffic. Weekend disruption was a small price to pay compared to what would have been regular road closures over four years with potential total closure of the interstate.

We need to look to progressive models such as this to ensure the effective provision of long-term protection to some of the UK’s bridges where the consequences of daytime closures are unthinkable. Through the use of new initiatives and innovations, including those developed by UK companies such as Stirling Lloyd, we can ensure that the structural integrity of bridges is protected for the intended design life with minimal disruption to road users.